Research

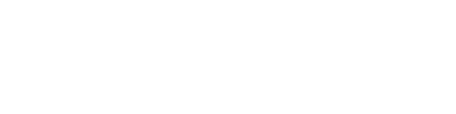

Functional materials with bond exchange concept

Conventional covalently cross-linked materials (i.e., thermosets) do not exhibit reprocessability, healability, and recyclability, due to the irreversible covalent bonded cross-links. To solve these problems, the studies of dynamic covalent bonds have been progressing. Among various species, “vitrimers” are a new class of cross-linked materials that are capable of network topology alternation through the “associative” dynamic bond-exchange mechanism(https://www.youtube.com/watch?v=Phanix8jPXI). Vitrimer concept provides the sustainable functions with cross-linked materials, which thus can contribute to realization of SDGs. We challenge further development of molecular designs and functionalizations, and also explore the precise tuning of bond exchange properties. Our aim is not only in these aspects, but also expanding the application range of vitrimer concepts into, for example, adhesion, forming, and composite.

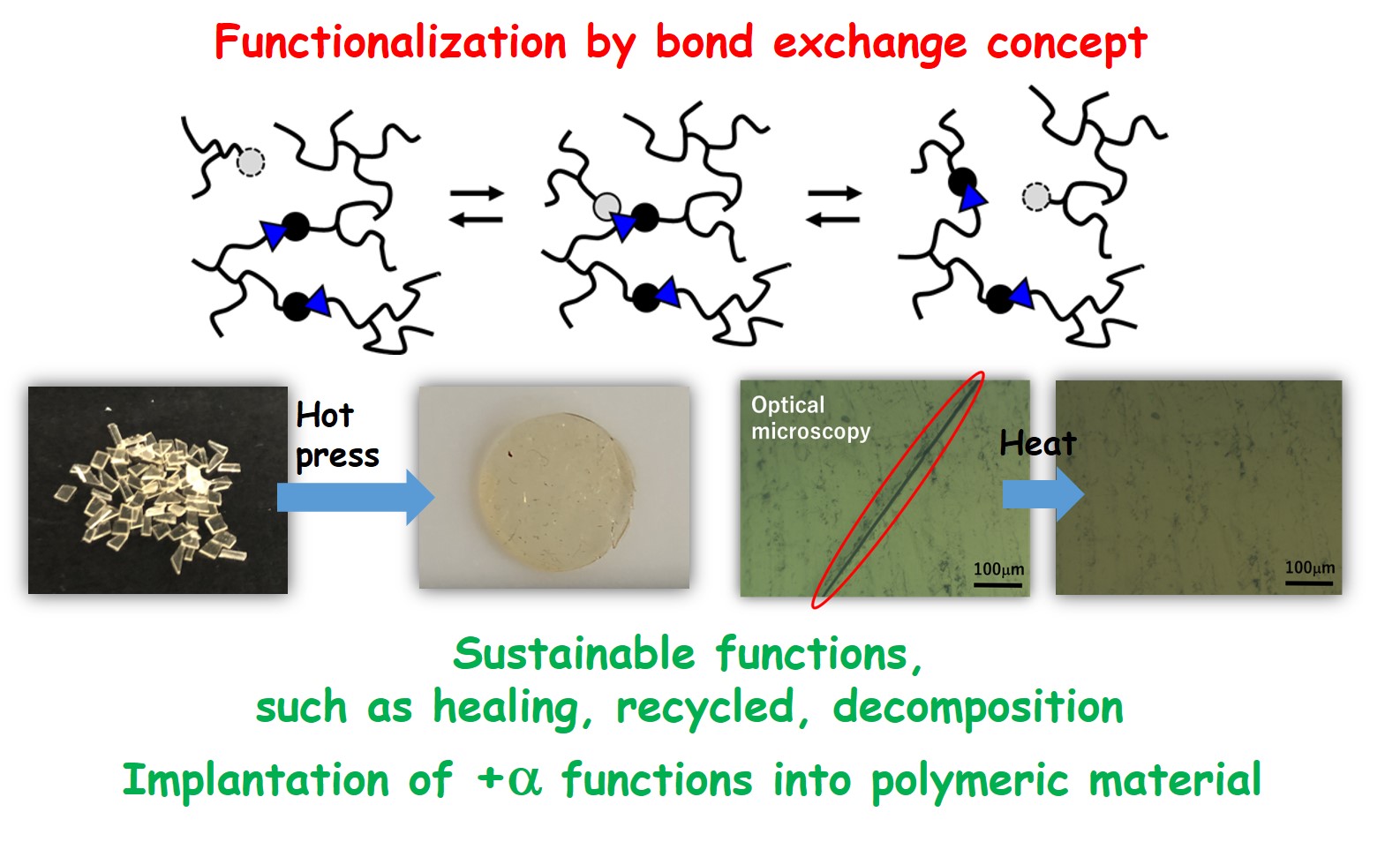

Upcycle technology

Since the establishment of SDGs in 2015, the awareness of plastic circulation has been regarded as an important issue. Recycling of plastics is one of the most effective ways for plastic circulation. Although social infrastructure for collection of used PET has been well constructed in many countries, a major fraction of collected PET is burned to obtain thermal energy (i.e., thermal recycle), and thus these materials end their life in one-time use. The reason is mainly the cost for recycling (collection, washing, and reprocessing) and reduction of physical properties during the recycling process. Therefore, the conventional recycling system is not attractive for business in the capitalistic economy. In our group, we develop a new recycling system (so-called, upcycling system) in which the material properties can be enhanced by material transformation to produce high-value materials (https://www.youtube.com/watch?v=CdBVQog9CRQ), which contributes to realization of sustainable society with a minimal loss of plastic resources.

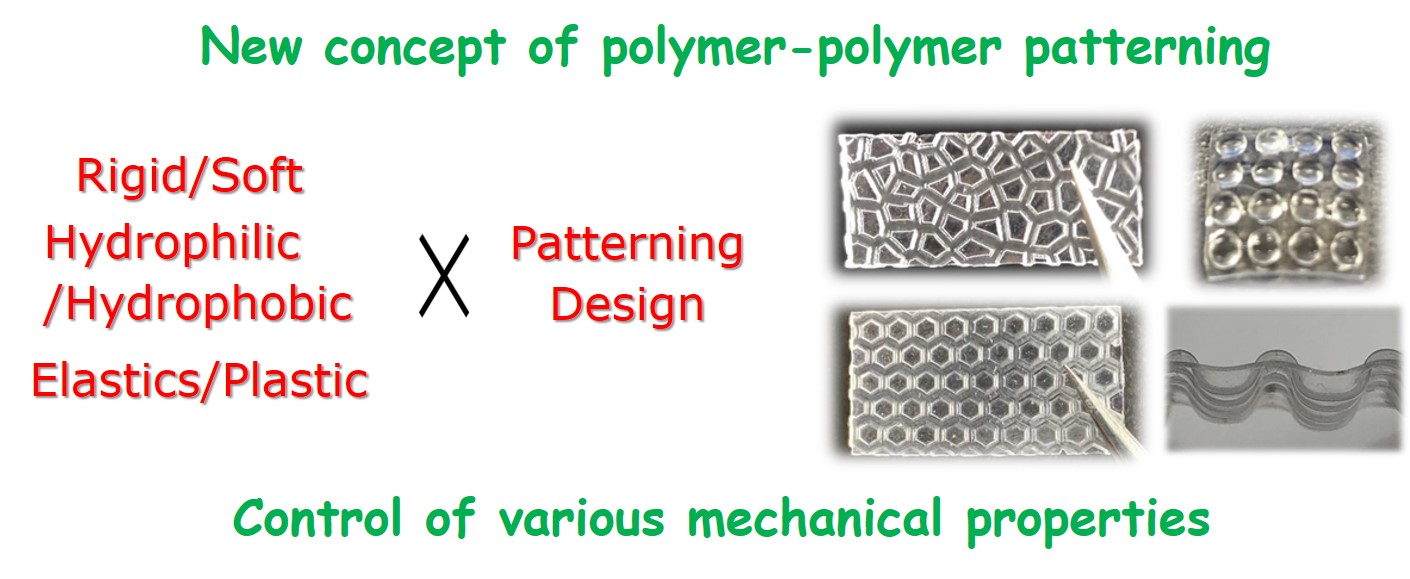

Control of mechanical properties by “patterning”

Recently, tough materials (long-life materials) have been highly required to deal with the depletion of petroleum resources and environmental issues. In addition, assuming further development of resinification of vehicles in the future, tough plastics must be attractive for safety reasons. Therefore, we study the methodology for toughness enhancement of polymeric materials (including elastomers and glassy polymers), by incorporating stress-dissipation mechanisms, such as the use of supramolecular weak bonds and special graft copolymer architectures. As another design, we develop patterning techniques of polymers using 3D-printer based area-selective polymerization (digital photo polymerization) and area-selective photo cross-linking, which can control some mechanical properties, such as toughness, fracture, and deformation.